HCA conference at the V&A, were you there? were you stuck in the snow? if you missed it this will give a brief taste. Thanks to Artisan media for filming and editing for us.

We are still working on collating all the comments into the manifesto and will post all the results here soon.

Monday 29 April 2013

Tuesday 23 April 2013

DCMS consultation crafts are not "creative"

DCMS have published a consultation paper on "Classifying and measuring the creative industries" frankly most of this stuff is boring but this time there is an element that craftspeople should be interested in. It is a consultation paper which means it is a proposal there to be changed.

The paper proposed dropping craft as a category of creative industry, the key statement in the paper is on p14

The paper proposed dropping craft as a category of creative industry, the key statement in the paper is on p14

"Most crafts businesses are too small to identify in business survey data, so while there has

been a crafts section in the former classification, we’ve not been able to provide GVA data.

.... We recognise that high-end craft occupations contain a creative element, but the

view is that in the main, that these roles are more concerned with the manufacturing

process, rather than the creative process. "

Librarians, computer programmers and marketing and sales directors are creative but craftspeople are not. Personally I find the hierarchy of "high-end craft" vs "manufacturing" poorly informed art-speak and look forward taking up the debate.

The GCA (Gross Value Added to the economy) data is a problem. The Crafts Council undertook their own research giving a GVA figure for the contemporary crafts of £220 million across the whole UK. Unfortunately the methodology used was not compatible with standard government methodology so can't be used in this context. The department of BIS commissioned research in Heritage Crafts giving a GVA of £4.4 Billion for just England.

The Heritage Crafts Association have been in consultation with our excellent contacts at BIS, DCMS and CCSkills and will be negotiating with the Creative Industries Council to hopefully win them over. In our experience adopting an adversarial position in these things rarely helps people change their minds. It is in their interest to represent a large sector the current estimate is 1,487,000 employees in the sector the heritage craft sector mapping includes 209,000 employees so far more significant that some of the groups they have included.

This shows the importance of all the work HCA undertook to push for the mapping project, it puts skilled craftwork on the government agenda and gives us exactly the figures we need to push for crafts to be recognised and taken seriously.

The consultation closes June 14th and we hope to be able to report a positive outcome.

Thursday 18 April 2013

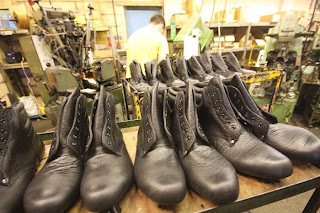

the last British bootmakers

This place is a real find and just down the road from me at Stoney Middleton. Folk know about them in the USA, Japan and London, I have driven past the door thousands of times but only just heard they were there, so join me on a tour of William Lennon bootmakers. They have been making boots in this old mill building since 1904, we were guided through by Libs the great grand daughter of William Lennon, it will be her who answers your email when you send your order for boots in as I am sure you will want to when you have seen this.

First the leather coming in, some from USA, some from India for the more price sensitive heavy work boots and some from the amazing Clayton's tannery at Chesterfield.

Pat does the closing, that is stitching the various bits of the upper together, and she has been doing it here for over 50 years!

It's a lovely old sewing machine, quietly and accurately stitching through two layers of really tough boot leather.

lots of lasts

downstairs now and these are tough workboots having the sole and upper united.

workboot uppers

These work boots are now ready to have rubber soles cast on to them. The rubber has a shelf life of 2 weeks and a big minimum order quantity so they have to build up a large stock then spend a week just doing rubber soles.

This machine casts the sole.

Now on to leather soled boots, I ordered a pair of these. This amazing sewing machine is stitching through nearly 1/2 an inch of leather.

This machine is fed with brass rood cut with a screw thread, it basically screws the leather sole and upper together more securely even than the famous good year welted sole. These are tough boots and will hold together even if they get worn down past the stitching.

a bott with vibram sole, if you click to expand this image you may be able to see that as well as the heavy stitching there is that row just inside of brass screwws holding it all together.

Hobnails! This pair of boots are in for repair, not what I would call a repair, basically all that is original is the uppers they have had complete new soles, lots of hand fitted hobnails and metal horseshoes front and back, they are not as good as new they are better than new because the uppers are already worn in to fit the user. I ordered horseshoes on mine but not the hobnails, they really are very noisy and pretty skiddy on a hard surface.

Another pair of boots in for the re-soling treatment. I love that they do this, I give footwear a hard life and wear boots out, my new boots will be paying intermittent visits to the place they were made for many years to come.

Here is my mate Andy choosing the leather for his boots, they don't normally offer this degree of customisation and having seen Andy dithering over all the potential options I can understand why.

I should show you the outside fo the mill, a typical Derbyshire limestone mill building, Can you imagine what it feels like to be working making boots in the same building four generations of your family have worked in? I love to see small scale manufacturing going on within local communities like this it just feels healthy and right somehow. Andy bought the mens traditional Derby boot

the ash tree, ash die back and ash bowls

I love ash trees, in particular weeping ash is one of my all time favourites though rarely planted today. Ash timber is incredibly versatile, strong and springy, over the years it has been used for all manner of things including the felloes (rims) of wooden wheels, axe and hammer handles, all manner of sports goods from hockey sticks to tennis rackets, the chasis of Morgan cars and thin strips can be used to weave baskets or as binding to tie stuff together such as besom brooms. On top of this it is great for furniture and the all time best firewood. Many folk think slow grown wood is better quality this is the case with softwoods but with hardwoods fast grown wood is significantly stronger than slow grown, the optimum for ash is 4-8 growth rings per inch.

The ash tree is the subject of a forthcoming book by this crazy guy Rob Penn who some UK wood fans will recognise as the presenter from BBCs tales from the wildwood.

For Rob's latest project he felled an ash tree and is setting off to get different things made from it that help him tell the story of the tree and man's relationship to it. I think it's a wonderful project and was thrilled that the first items made from the tree were a set of my nested bowls. Rob arrived by train and bike with a very serious chunk of ash in his backpack.

I cut the tree up and then turned a nest of bowls.Rob with his bowls.

Ash was the most commonly chosen timber for bowls during medieval times, I don't use it so much today but these bowls turned out nice so maybe I should do it more. Here is a typical ash bowl from medieval London.

Folk may have read doom-laden reports in the press about ash die back disease and how all our ash trees are going to die.

I have been involved in forestry long enough to read the catastrophic prophesies on diseases affecting sweet chestnut, alder, oak, horse chestnut (those all in the last 10 years) all were proclaimed as the next dutch elm disease, all have proved to be problematic but not catastrophic. Ash die back could be different, it could kill a lot of trees or it might not. The comparisons with Denmark where most trees died are not relevant those trees were primarily forestry trees of uniform age and limited genetic diversity, we have yet to see how it reacts in our natural genetic diverse population, in Sweden around 50% of the trees have noticeable damage and 25 percent are severely injured. Even if we accept the worst case scenario and we have let something truly grim loose then running around stressing is not going to help anyone, if all the ash were to die their places would be taken by other trees as the spaces in our woodlands were filled when the elms died, can anyone show me a gap in a woodland where the elms were?

The other idea that is touted about which is silly is the idea that if we can somehow slow the spread down then it gives us time to do something about it. Well this is twaddle. Fungal diseases affecting trees mutate and change rapidly, it is not in their interest to wipe out the host entirely, trees do not develop immunity think about the length of lifecycle of the fungus and the tree and think which is going to change first. The whole delaying spread so we can develop resistant strains thing is about as silly as suggesting we can hold back this years strain of flue whilst we humans develop resistance.

The wise approach to ash die back is to admit that we don't know yet what it will do, there is nothing we can do about it but that whatever happens the combination of nature and foresters will deal with it without drama. Forestry is a long term game, selling news stories is of the moment. No one will get on the TV for saying let's sit back and wait and see. Or as leading woodland historian Oliver Rackham has said "What is to be done? Probably nothing effective in the present state of ignorance."

My last word on the subject must include a rant about the tree planting business. I call it a business because that is what it is, a large scale industrial business with many vested interests making money. People love to plant trees, if you fence stock out of anywhere in lowland Britain and wait it will become woodland surprisingly quickly through natural regeneration with local genetic stock but people are impatient so we buy trees from nursaries. We don't ask too much about those trees, if we want to hear they are local seed types and ask they will tell us they are and we are unlikely to ask for proof. I have planted "native dogwood" in a hedge only to find it come out in spring with variegated leaves. The nursery trade has grown up with serving an ignorant public who do not ask enough questions and are often not in a position to know if their ash is native or not, we have to trust the nurseryman and sadly we can't. The result of this is that there is now global trade and movement of tress and tree diseases. Trees and their parasites and pathogens have evolved over millennia together, when we start moving stuff around it causes problems, this has been proven many many times but we have done nothing about it. We have been sending ash seed to be grown in Holland and reimporting infected trees probably for some considerable time.

If there is any intelligent action to be taken over ash die back it would be increased regulation of the nursery trade and re-educating the well meaning public and various woodland charities so that they understand that tree planting is not often a very good thing to do. I say that as someone who has planted well over 10,000 trees, most of which I now realise would have been better not planted.

Friday 12 April 2013

practice, passion, dedication

Last year this video did the rounds on the internet, you may have seen it before, if you haven't then you are in for a treat.

I absolutely loved it at the time and now I love it all the more and this is why. I just found the facebook page for Marquese Scott and there are lots of similar vids, many of them low budget jobs from a couple of years ago but also a great interview with him which just says lots about how to get good at anything.

So what kept you dancing?

"Just the passion. Like the love for it that I felt when I was out there dancing. Like most people they would dance and if it doesn't pick up for them in like a couple of years they will loose interest because they are not gaining fruits from it you know, but I loved ir so much that I just stuck with it. It's like forget what everybody has to say you know you just got to follow your dreams and it's gonna happen one day you know"

So Marqueez do you have anything to say to future dancers right now? anyone who really looks up to you?

"I would have to say like I have been doing this for 18 years cos I was 12 years old, and it's not going to come overnight you have to stick with it. So what I would say to everybody is if you love it and its a passion, no matter what it is, it could be dance, it could be art. it could be music, whatever it is just stick with it and if you do it long enough and you get good at it success will come, you know what I am saying? so just stick with it....dedication, that's what I have to tell you guys."

here's the interview

and one more bit of dance

The message to me is do it for the passion, do it lots and keep doing it, do it for the love of doing it. That is the only thing that will keep you going for the years it takes to get really good at anything. Most people who get good at most things get little recognition or financial payback for it anyway so don't hope for or expect those things, if you genuinely love what you do that is reward enough.

Wednesday 3 April 2013

Crafted Makers of the Exceptional opens London tomorrow

CRAFTED SHOWCASE

The inaugural Crafted: Makers of the Exceptional showcase is an important retrospective and celebration of the work of some of Britain’s most talented craftmakers. Bringing together those who have been supported by Walpole British Luxury through the Crafted mentoring programme, the showcase provides a glimpse into the inner workings of Britain’s finest craft businesses – from knitwear and jewellery to lapidary and glass blowing.

Sponsored by Vacheron Constantin, one of the world’s oldest and most respected manufacturers of luxury Swiss timepieces, the showcase is free of charge to visit and open to all.

The craftmakers workshop spaces are recreated in Somerset House’s West Wing and tell the story behind each stage of the craft-making creative process – from raw material to finished work. The focus is on the people as well as the products with live demonstrations and chances to meet the makers expressed in four simple themes: A Craft Perfected; A Tradition Preserved; A Life Devoted and A Business Nurtured.

The showcase is held concurrently with Vacheron Constantin’s Métiers d’Art days taking place on Thursday 4th to Saturday 6th April in France, Italy, Switzerland and Spain. These annual exhibitions are dedicated to promoting and passing on the culture of over 200 skills, many of which are centuries old.

Image courtesy of exhibitor Jessica Poole

Follow Walpole British Luxury on Twitter and Facebook

Follow Walpole Crafted on Twitter and Facebook

#CraftedShowcase

Follow Walpole Crafted on Twitter and Facebook

#CraftedShowcase

Subscribe to:

Posts (Atom)

.jpg)